Siddhi Rubber Udyog's Nonwoven Geotextile Expertise

Established in 2014, Siddhi Rubber Udyog has carved a niche in the construction industry through its commitment to quality and innovation. Their expertise in Nonwoven Geotextiles encompasses:

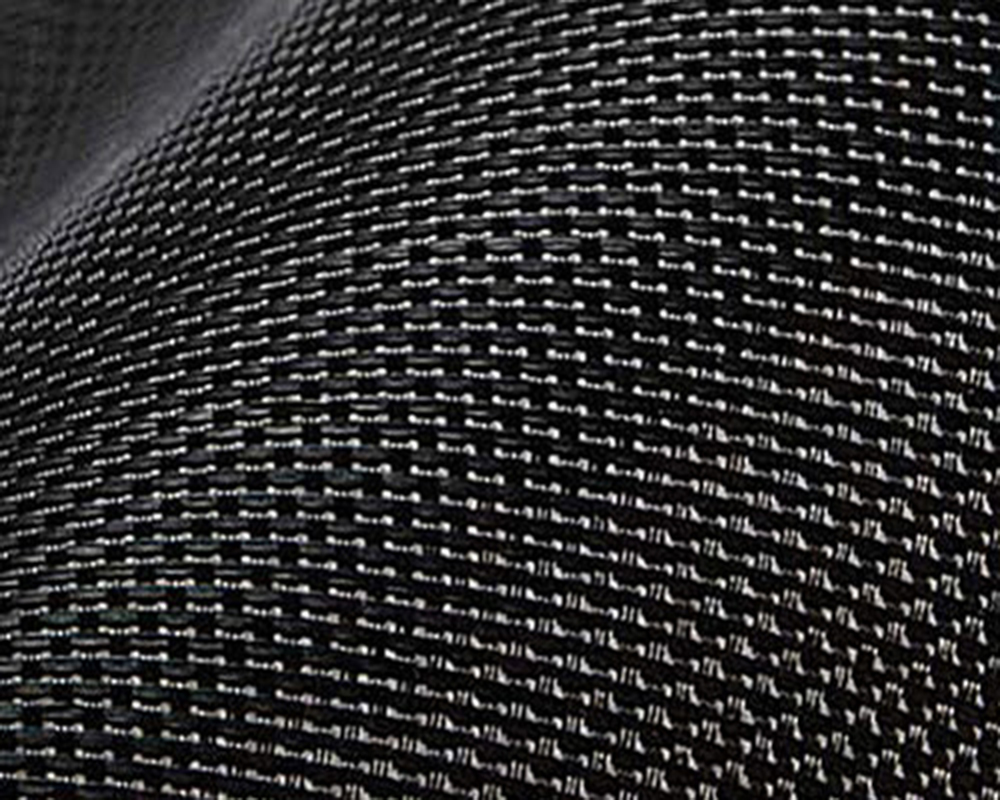

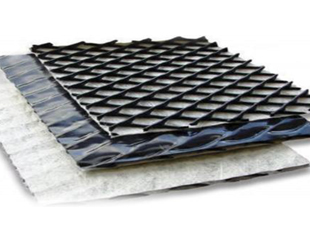

Manufacturing: They employ cutting-edge technologies to produce high-performance Geotextiles with varying strengths, thicknesses, and permeabilities to cater to diverse project requirements.

Supplying: They maintain a well-stocked inventory to ensure prompt delivery of Geotextiles to projects across India.

Dealing: Their experienced team offers valuable technical guidance and assists in selecting the optimal Geotextile solution for your specific needs.

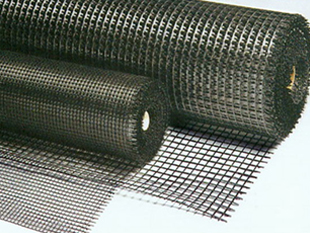

Siddhi Rubber Udyog's Nonwoven Geotextiles are available in a wide range of specifications, including:

Basis Weight (GSM): This refers to the fabric's weight per square meter. Siddhi Rubber Udyog offers Geotextiles ranging from lightweight (30 GSM) for filtration applications to heavyweight (400 GSM) for heavy-duty reinforcement.

Roll Width: Their Geotextiles come in various widths to suit project requirements and minimize wastage.

Color: Typically, Nonwoven Geotextiles are white or black.

Applications of Nonwoven Geotextiles from Siddhi Rubber Udyog

Siddhi Rubber Udyog's Nonwoven Geotextiles find application in a broad spectrum of civil engineering and construction projects, including:

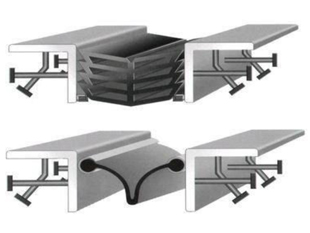

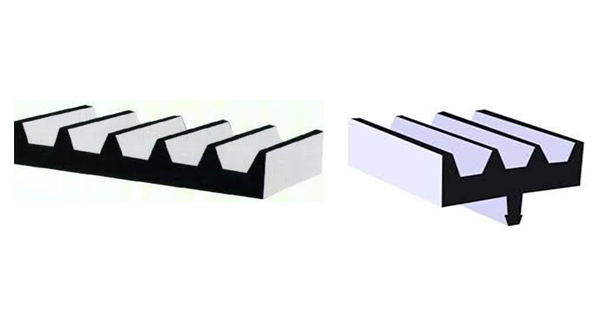

Road Construction: Separation of subgrade and base course materials, filtration, and reinforcement.

Railroad Construction: Track bed stabilization, drainage, and erosion control.

Landscaping: Slope stabilization, erosion control, and drainage for retaining walls and embankments.

Drainage Applications: Drainage channels, swales, and landfill liners.

Environmental Applications: Erosion control for shorelines, riverbanks, and canals.

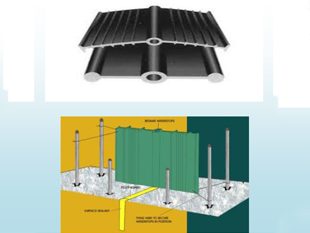

Building Construction: Foundation drainage, waterproofing membranes, and green roofs.

Why Choose Siddhi Rubber Udyog for Your Nonwoven Geotextile Needs?

There are several compelling reasons to partner with Siddhi Rubber Udyog for your Nonwoven Geotextile requirements:

Quality Products: They prioritize quality by utilizing premium raw materials and stringent manufacturing processes.

Extensive Experience: Their years of experience ensure a thorough understanding of Nonwoven Geotextile applications and their optimal use.

Comprehensive Solutions: They offer a one-stop shop for all your Geotextile needs, from manufacturing and supply to technical guidance.

Competitive Prices: They strive to provide high-quality products at competitive prices, ensuring value for your investment.

Customer Focus: They prioritize customer satisfaction and provide excellent technical support throughout the project lifecycle.

Frequently Asked Questions

What are the different types of Nonwoven Geotextiles offered by Siddhi Rubber Udyog?

Siddhi Rubber Udyog primarily deals with nonwoven geotextiles. However, within this category, they offer variations based on:

Basis Weight (GSM): Ranging from lightweight (30 GSM) for filtration to heavyweight (400 GSM) for reinforcement.

Roll Width: Available in various widths to suit project needs and minimize offcuts.

Can Siddhi Rubber Udyog customize Nonwoven Geotextiles in Mumbai?

While extensive customization might not be possible, Siddhi Rubber Udyog offers a variety of specifications within their existing product range. They can help you choose the most suitable geotextile based on your project's requirements like basis weight and roll width.

Does Siddhi Rubber Udyog provide installation services for Nonwoven Geotextiles?

Siddhi Rubber Udyog primarily focuses on manufacturing, supplying, and offering technical guidance for Nonwoven Geotextiles. For installation, they might recommend qualified contractors in your area.

What are some alternative suppliers of Nonwoven Geotextiles in India?

Several companies in India manufacture and supply Nonwoven Geotextiles. A quick web search can help you find a list of potential suppliers in your region.

How long do Nonwoven Geotextiles typically last?

The lifespan of Nonwoven Geotextiles depends on factors like material quality, UV exposure, and installation methods. Generally, they can last for several years when installed correctly.

.png)

.jpg)

.jpg)

.jpg)

.jpg)